How can we please both parents and children when we're talking about food? It's a struggle every parent is familiar with: feeding children healthy food on a regular basis which they can hopefully also enjoy! While it would be ideal to have all the time and resources in the world to experiment, busy schedules do not always allow for the time it takes to properly prepare and feed healthy meals to children - and having a picky eater on one's hands can be particularly upsetting to the daily routine of parents.

Trying to appease the taste-buds of both adults and children is no easy task, and finding family-pleasing foods can become increasingly complicated as children grow older. While little ones may be in constant want of hamburgers, pizzas and sweets, parents can look for healthier alternatives that will be equally appetizing. Education is the basis for ensuring children are receiving adequate nutrition and acquiring healthy eating habits. Some recommendations to follow are:

- Take the time to prepare healthy homemade meals

- Experiment with different recipes

- Discover different ways of making food!

A healthier solution

As the food industry and general public become increasingly aware of health-conscious trends and social concerns around health issues such as the rise of diabetes or childhood obesity, research is being invested into practical solutions. To meet consumer demand for healthier food, a wide majority of the food sector is looking to produce minimally processed products - without additives, and with the freshness, nutritional density and sensory experience of fresh, whole foods. In the search for processes that can maintain those qualities, the food industry has adopted HPP technology.

What is High-Pressure Processing? (HPP)

HPP or high-pressure processing technology is a discovery that dates back to 19th century Japan. However, it was not until the end of the twentieth century that it attracted real interest in the food industry. In the 21st century, it has become the chosen resource for prestigious worldwide brands.

HPP is a method of preserving food and beverages in their packaging, similar to thermal pasteurization. But, unlike thermal pasteurization, HPP does not use heat. Instead, it processes food by applying high hydrostatic pressure (with water).

The peculiarity of hydrostatic pressure is that it is transmitted uniformly and instantly to all points of the product, without creating or breaking covalent bonds. However, it modifies weak bonds present only in macromolecules such as proteins or polysaccharides. In short, thanks to these characteristics and the fact of application in a packaged product, high-pressure processing makes the following benefits possible:

- To produce safer food with a longer shelf-life, thanks to the inactivation of common microorganisms such as Listeria, E. coli or Salmonella.

- To preserve the organoleptic and nutritional qualities of products, because there is no degradation by heat of the food components.

- To reduce and even avoid the use of preservatives and other chemical compounds.

Where is HPP being-used today?

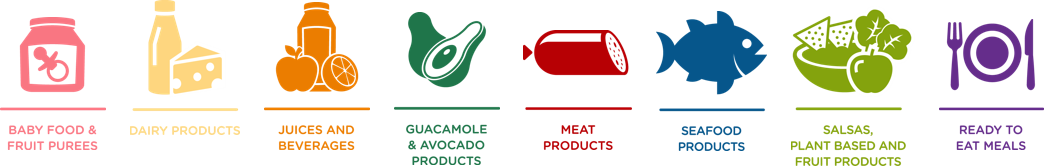

HPP technology can be applied in almost every known food category:

Baby foods, in particular, have become one of the categories with the greatest growth potential, as HPP allows the production of natural, healthy baby foods that retain all their nutritional value, and are ready to eat and adapted to all ages. In addition, it guarantees food safety and a long shelf-life, reducing or eliminating the use of additives such as sugar or preservatives.

Worldwide brands such as Impress, Del Monte, Mush, Bright Foods and B.Fresh are already using HPP technology. On February 24 (11am EST / 8am PST / 4pm UK), two brands will participate in a free webinar organized by Hiperbaric, the world's leading supplier of HPP technology. They will share their professional and personal relationship with high hydrostatic pressures.

To learn more

If you have any questions you can always ask them in the question and answer round of the webinar or send them to Hiperbaric through this form. Expert food technologists will answer you without delay!